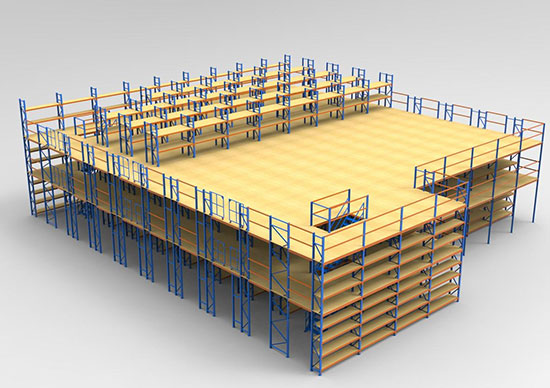

Build a middle loft on the existing racking or work site to increase the storage area. E-commerce warehouse storage can be built as two or three floors. E-commerce warehouse storage is suitable for multi-variety large-volume or multi-variety small-batch goods, manual storage and retrieval of goods. The goods are usually delivered to the second and third floors by forklifts, hydraulic elevators or freight elevators, and then delivered to a certain location by light trolleys or hydraulic pallet trucks. This type of rack system usually uses medium-sized shelf racks or heavy-duty shelf racks as the support of the main body and floor slabs (depending on the total load capacity of the unit racks to decide which rack to choose), the floor slabs usually use cold rolled steel floor slabs and pattern steel floor slabs Or steel grille floor. This type of E-commerce storage solutions have many applications in the field of auto parts, auto 4S shops, light industry, electronics and other industries.

The customer in this case is an e-commerce company. The warehouse height is 8300-9000mm, and the rack height is nearly 8000mm. The whole shelf system is divided into three layers: the ground floor, the first floor and second floor. Each floor is equipped with a pedestrian staircase, and aisle. The elevator can carry goods up to the top floor. The entire e-commerce storage solutions cover a total area of 3,000 square meters.

For more custom selections of e-commerce warehouse storages, please contact Maobang warehouse rack supplier

Warm reminder: Rack-supported racking and mezzanine have requirements for the height of the warehouse, which is more suitable for small goods, manual access, large storage, lighting, fire protection and other issues need to be considered.

Ecommerce businesses thrive on effective warehouse storage solutions that maximize space utilization, reduce costs, and streamline operations. With the ever-growing demand for online shopping, it has become imperative for businesses to optimize their storage capabilities. By implementing efficient ecommerce warehouse storage practices, companies can significantly enhance their operational efficiency, customer satisfaction, and ultimately their bottom line. In this article, we will explore five different ecommerce warehouse storage solutions that help businesses save space and money.

E-commerce Storage Solutions Improve Ecommerce Storage Tech Stack

Investing in advanced technology solutions can revolutionize ecommerce warehouse storage. Automated systems, such as barcode scanners, radio frequency identification (RFID), and inventory management software, enable accurate tracking, efficient order fulfillment, and seamless inventory management. By implementing these technologies, businesses can optimize space usage, reduce errors, and save costs associated with manual labor and inventory inaccuracies.

E-commerce Storage Solutions with Streamline Product Selections

Organizing products based on their popularity and demand can save significant storage space. By analyzing historical data and implementing intelligent inventory management systems, businesses can strategically position fast-selling products in easily accessible areas of the warehouse. This reduces the need for excessive storage space and minimizes the time taken to retrieve items, leading to improved order fulfillment and customer satisfaction.

Multiple Warehousing Locations for E-commerce Storage Solutions

Establishing multiple warehousing locations can help businesses serve customers more efficiently and reduce shipping costs. By strategically locating warehouses closer to target markets, businesses can minimize transportation time and expenses. Additionally, distributing inventory across multiple locations allows for faster order fulfillment and reduces the risk of stockouts, enhancing overall customer experience.

Outsource for Faster Scaling with E-commerce Storage Solutions

Outsourcing warehousing and fulfillment services to third-party logistics providers (3PLs) can be a cost-effective solution for businesses experiencing rapid growth. 3PLs specialize in handling warehousing and distribution operations, allowing businesses to focus on core competencies. This approach eliminates the need for investing in infrastructure, equipment, and additional labor. By leveraging the expertise of 3PLs, ecommerce businesses can scale rapidly without incurring excessive costs.

Reduce Failure and Spoilage Risks by E-commerce Storage Solutions

Certain products, such as perishable items or products with expiration dates, require specialized storage conditions. By investing in temperature-controlled storage facilities or partnering with specialized warehousing providers, businesses can minimize spoilage and reduce product failure risks. Properly storing and preserving goods not only prevents financial losses but also helps maintain the quality of products, leading to improved customer satisfaction and loyalty.

Be Organized with Self-Storage Units

For smaller ecommerce businesses or those operating on a limited budget, self-storage units can provide a flexible and cost-effective solution. These units offer secure storage space that can be rented on-demand, allowing businesses to adjust their storage needs as per the inventory volume. Self-storage units are particularly beneficial for seasonal businesses or those with fluctuating inventory levels. They provide a scalable storage solution without the overhead costs associated with long-term leases.

In the fast-paced world of ecommerce, maximizing warehouse efficiency is crucial for businesses to meet customer expectations, minimize costs, and drive profitability. By implementing effective strategies and optimizing warehouse operations, businesses can streamline processes, improve inventory management, and enhance overall efficiency. In this article, we will explore five different ecommerce warehouse storage solutions that can help maximize warehouse efficiency.

Implement Warehouse Management Systems (WMS) with E-commerce Warehouse Storage

One of the most effective ways to enhance warehouse efficiency is by implementing a robust Warehouse Management System (WMS). A WMS automates various processes, such as inventory tracking, order fulfillment, and warehouse optimization. It provides real-time visibility into inventory levels, improves picking accuracy, and optimizes storage space utilization. By utilizing a WMS, businesses can streamline operations, reduce manual errors, and increase overall productivity.

Optimize Warehouse Layout and Design with E-commerce Warehouse Storage

The layout and design of a warehouse play a critical role in maximizing efficiency. Analyzing product flow patterns, customer demand, and order fulfillment processes can help determine the most effective layout. Consider implementing strategies such as cross-docking, zone picking, and ABC analysis to optimize picking routes and reduce travel time. Additionally, using vertical storage solutions, such as mezzanine shelf and high-density racking systems, can maximize space utilization and increase storage capacity.

Embrace Lean Inventory Management with E-commerce Warehouse Storage

Maintaining optimal inventory levels is essential for warehouse efficiency. Embrace lean inventory management principles, such as just-in-time (JIT) and vendor-managed inventory (VMI), to reduce excess stock and minimize storage requirements. Conduct regular inventory audits to identify slow-moving or obsolete items that can be liquidated or discontinued. By adopting lean inventory management practices, businesses can free up valuable storage space, reduce carrying costs, and improve overall efficiency.

Utilize Automation and Robotics with E-commerce Warehouse Storage

Automation and robotics technology can significantly enhance warehouse efficiency. Consider implementing automated conveyor systems, robotic picking systems, and automated guided vehicles (AGVs) to streamline order fulfillment processes and reduce manual labor requirements. These technologies increase picking accuracy, accelerate order processing, and optimize storage space utilization. By leveraging automation and robotics, businesses can improve overall operational efficiency and throughput.

Implement Slotting Optimization with E-commerce Warehouse Storage

Slotting optimization involves analyzing product characteristics, demand patterns, and storage capacities to determine the optimal storage locations for different items within the warehouse. By placing fast-moving products near picking stations and organizing items based on size, weight, and demand, businesses can reduce travel time and increase picking efficiency. Regularly review and update slotting configurations to adapt to changing product demands and optimize warehouse operations.

Emphasize Continuous Training and Process Improvement with E-commerce Warehouse Storage

Investing in employee training and fostering a culture of continuous improvement can significantly impact warehouse efficiency. Train employees on proper inventory handling techniques, use of warehouse storage equipment, and safety protocols. Encourage feedback from warehouse staff to identify bottlenecks or areas for improvement. By empowering employees and implementing their suggestions, businesses can optimize processes, enhance productivity, and improve overall warehouse efficiency.

Warehouse management for ecommerce refers to the comprehensive set of processes and strategies employed to efficiently manage and control inventory within a warehouse specifically tailored for ecommerce operations. It involves the coordination of various tasks, such as receiving, storing, picking, packing, and shipping of products, with the aim of optimizing warehouse operations, improving order fulfillment speed, and enhancing customer satisfaction. Warehouse management is critical for e-commerce businesses as it directly impacts their ability to meet customer demands, minimize costs, and maintain a competitive edge in the online marketplace.

Warehouse management for ecommerce encompasses a range of strategies and practices that aim to optimize inventory control, streamline operations, and enhance customer satisfaction. By implementing inventory management and tracking systems, optimizing space utilization, streamlining order fulfillment processes, optimizing warehouse layout, and integrating technology solutions, businesses can effectively manage their warehouses and ensure seamless ecommerce operations. These solutions contribute to faster order fulfillment, improved inventory accuracy, reduced costs, and ultimately, a better customer experience.

Long Goods: long product storage

Garment/Clothing: warehouse garment rack

Cold & Frozen Goods: cold storage racking

Automotive & Spare Parts: auto parts storage systems

Food & Beverage: food warehouse storage

Transport & Logistics Operators: warehousing and storage in logistics

Galvanized Steel Pallet In Carton Factory

E-Commerce