(1) The general situation around the installation site should be understood, especially the transportation roads, power line layout, etc.

(2) On-site roofing and internal painting and other works should be basically completed, the relevant foundation floor and trench should have been completed, and the concrete strength should not be less than 75% of the design strength; there should be no debris on the construction site and nearby ,Rubbish.

(3) When using the building structure as the most lifting bearing point or using other equipment, the owner's consent is required.

(4) Prepare the required tools in advance, the quantity depends on the size of the project

(1) Before unpacking or unpacking, check the "packing list" and make a record. If loose packages, damages, or serious damages are found, report them in time and take photos and make records and feedback to the manufacturer

(2) All goods should be inspected when opening the package, the size and quantity should be checked, and any errors should be reported in time

(3) The components of the shelf should be stored in a dry and cool place, avoid direct sunlight and rain.

(4) When handling equipment such as forklifts, cranes, etc., operate carefully to avoid damage to the goods

(5) Small parts should be kept properly, and they should not be deformed, damaged, disordered or lost

Here are some steps that warehouse racking manufacturer will do during acceptance works.

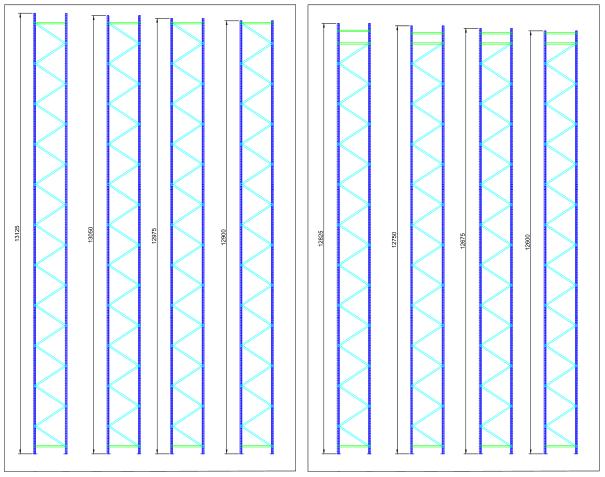

(1) Check whether the overall size of the racking shelf is consistent. Use a tape measure to measure the length of the shelf column and beam. It should be noted here that there is a difference between the inner and outer dimensions of the rack, and you must first confirm with the rack manufacturer whether to measure according to the inner or outer dimensions;

(2) Check the quality of the rack material to see if it is bent or deformed. However, some bumps in the goods during transportation are unavoidable. If the material is just a few potholes, it is normal.

(3) Check the overall installation accuracy of the rack, the vertical deviation of the rack pieces is not more than 10mm, the height deviation of the same layer beam is ±10mm, the center distance between the bottom of the adjacent rack pieces is ±2mm, and the misalignment deviation of the same row of the same lane in the same lane is not more than 5mm;

(4) The column piece is usually welded at the time of the manufacturer. The weld on the surface of the rack is a test of the shelf manufacturer’s production capacity. It must be uniform, and there should be no cracks, slag inclusions, weld bumps, burn-through, arc craters and needles. Defects like pores, etc., must be carefully observed during acceptance.

(5) Check the surface spraying quality of storage racks The surface treatment is easy to see. The purchaser can directly check whether the surface meets the requirements with the naked eye, or hit the surface of the rack with a hammer to see if there is any fall off, so as to confirm whether the spraying of the shelf manufacturer meets the usage standards;

(6) Check whether the racks are tightly installed, whether the beams and layers are flat, whether the beams and columns are clamped well, and whether there are quality problems.

1. Check the delivery note and the actual quantity delivered, and observe whether the accessories on the racks are intact.

2. First look at the installation drawings carefully, understand the general structure of the warehouse rack, and sort out the installation sequence.

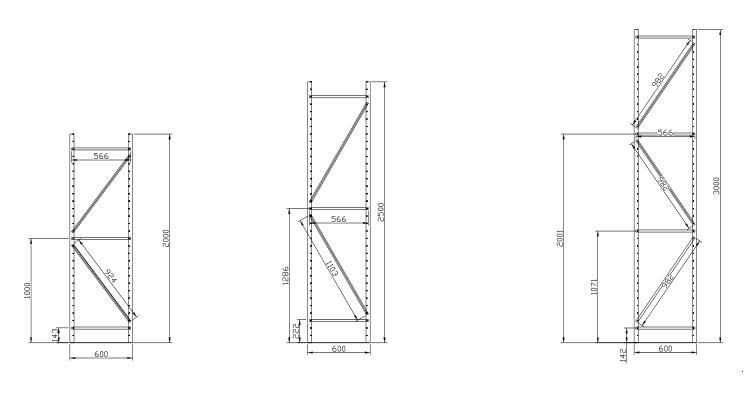

3. Begin to assemble the column first, and install the foot pads on the column first.

4. Then assemble the top and bottom triangles. Use the screws to install the triangles on the column, but don't tighten the screws too tight, just bring them on, so that you can adjust them after all assembly is completed.

5. Then assemble the top and bottom load-bearing plates, which can also be attached with screws, don’t tighten them too tightly.

6. Next, assemble the middle load-bearing plate and place it in the middle at an angle, and place it in a suitable position according to the design of the floor height. Then use the screws to bring the triangle, the load-bearing plate and the column together, or do not tighten the screws too tightly.

7. Finally, stand the racking up and keep it vertical against the wall. Then tighten the screws gradually from the bottom up. After all the screws are tightened, you can shake the shelf with both hands to see if the shelf is stable. After the shelf is stable, the assembly is completed.

1. Reserve an area for the rack shelves, try not to put the shelves outside in the sun or rain.

2. Keep the installation site tidy and clean up dust and garbage.

3. Level the ground before assembly to ensure the stability of the shelf installation. The smoother the ground, the better.

4. Pay attention to lifting and placing gently to avoid bending and deformation of the shelf or abrasion of the surface spray