The use of storage racking is widely used in many companies now. Racking shelves are made of steel and most of them are disposable equipment. Many people only know how to increase the warehouse space and the convenience of storing goods by using shelves, but do not know how to maintain the shelves and extend its service life.

Anti-collision protection

Most of the most easily damaged racks are the aisles and the columns at the corners, which are usually deformed by the forklift. According to different racks, aisle widths and transportation tools, the industrial shelf suppliers have matching anti-collision feet and anti-collision rail equipment. Crash barriers should be installed in the passage. The installation of anti-collision rails and anti-collision feet play a very important role in protecting the column.

Anti-stress

In Maobang warehouse racking manufacturer, The racking shelves of different specifications are designed and manufactured according to the load-bearing design. Therefore, the weight of the goods placed on the rack must be within the allowable range of the rack load. It is best for the warehouse manager to mark the load-bearing limit on the racking shelf. Follow the principle of heavier on the bottom of the racking that is, put heavy objects on the bottom layer and light objects on the upper layer.

Moisture-proof

Sun-proof and rain-proof. Although the columns, beams and laminates of the shelves are all metal products, and the surface is painted, but after being exposed to moisture and sun, they may rust over time and affect their service life. Even if the shelf layer is made of wood, the position near the window is most likely to receive rain, and the wood will deform and warp after rain.

Require special personnel to use push-up trucks

In particular, heavy-duty and high-rise warehouses must be equipped with powered push trucks, and the use and operation of push trucks must only be operated by qualified personnel. Most of the warehouse rack columns are deformed due to the use of pusher trucks by non-designated personnel. In addition, the shelf beams are best customized to be yellow for identification by the operator of the pusher.

Specify the standard pallet size and delivery size

Commonly used pallet size width is between 0.8-1.2 meters. For example, the beam of the heavy beam type rack is generally 2.5/2.7 meters, and is designed according to the width of two pallets on one layer. If the pallet used is non-standard. Or the size of the goods placed on it exceeds 1.2 meters, and it may hit the column when it is jammed or pulled on the shelf.

Prescribe racking shelf use system

Different warehouses and different racks have different usage methods. The warehouse manager should formulate a racking shelf use system, so that every racking user can learn and abide by it, in order to finally achieve the goal of protecting the racking shelf.

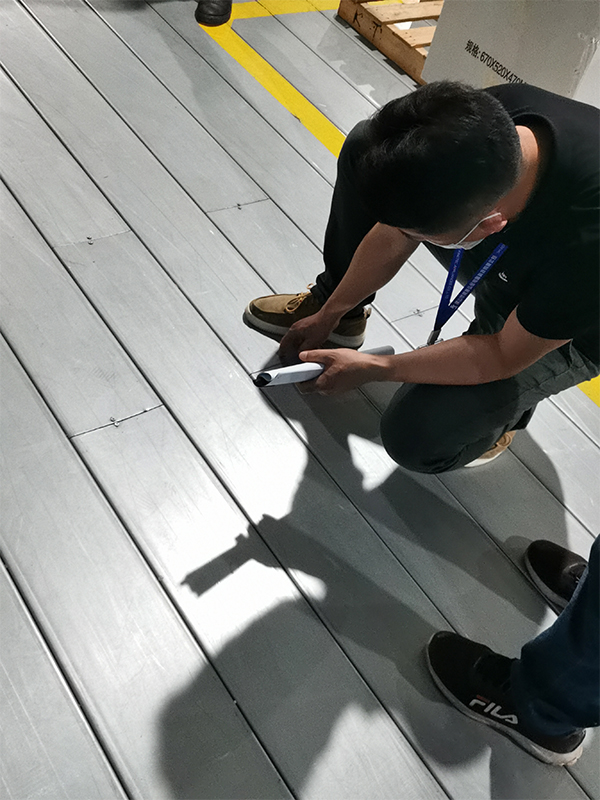

No matter when and where to design and install the rack, it is necessary to detail the documents that are most safely carried by the racks, and these documents are not easy to be obtained by the staff responsible for the operation and maintenance of the racking shelf. In order to prevent the emergence of unsafe operating conditions, we generally place warning signs in conspicuous places.

The content of the warning sign is generally:

1. What is the maximum allowable weight of the storage unit and the maximum average load of each layer?

2. The maximum load of each unit racking shelf

3. Is it possible to stack the storage marks for storage

4. Contents that need special instructions for each specific use environment

A better way to do these warning signs is to place one for each layout in each lane. Because there may be different rack structures in the same aisle.

The number of racking shelf cross braces is determined by different column heights and load-bearing capacity, and they are mainly triangular in shape to achieve the most stable state. Different manufacturers have different designs and need to be installed according to the drawings provided by the manufacturers.

There are two types of backstop rods of the rack:

Safety backstop bar: Prevent collision with other goods placed on the racking shelf when the goods are accessed. If the racks are properly designed and the operating space between the racks and the racks is large enough, the safety backstop bar is not a necessary accessory.

Buffer backstop: assist forklifts or other handling equipment to accurately place pallets or goods on the shelves. It does not need to keep any distance from the tray position, but it acts as a buffer.

Because most of the storage racks in the logistics center are heavy-duty racks, forklifts and other warehousing equipment are needed to assist in storing and unloading goods. Large-scale equipment such as forklifts, if the collision intensity is high, may cause the storage shelves to deform and collapse. Therefore, storage rack manufacturers will recommend the installation of protective fences or pillar protection.